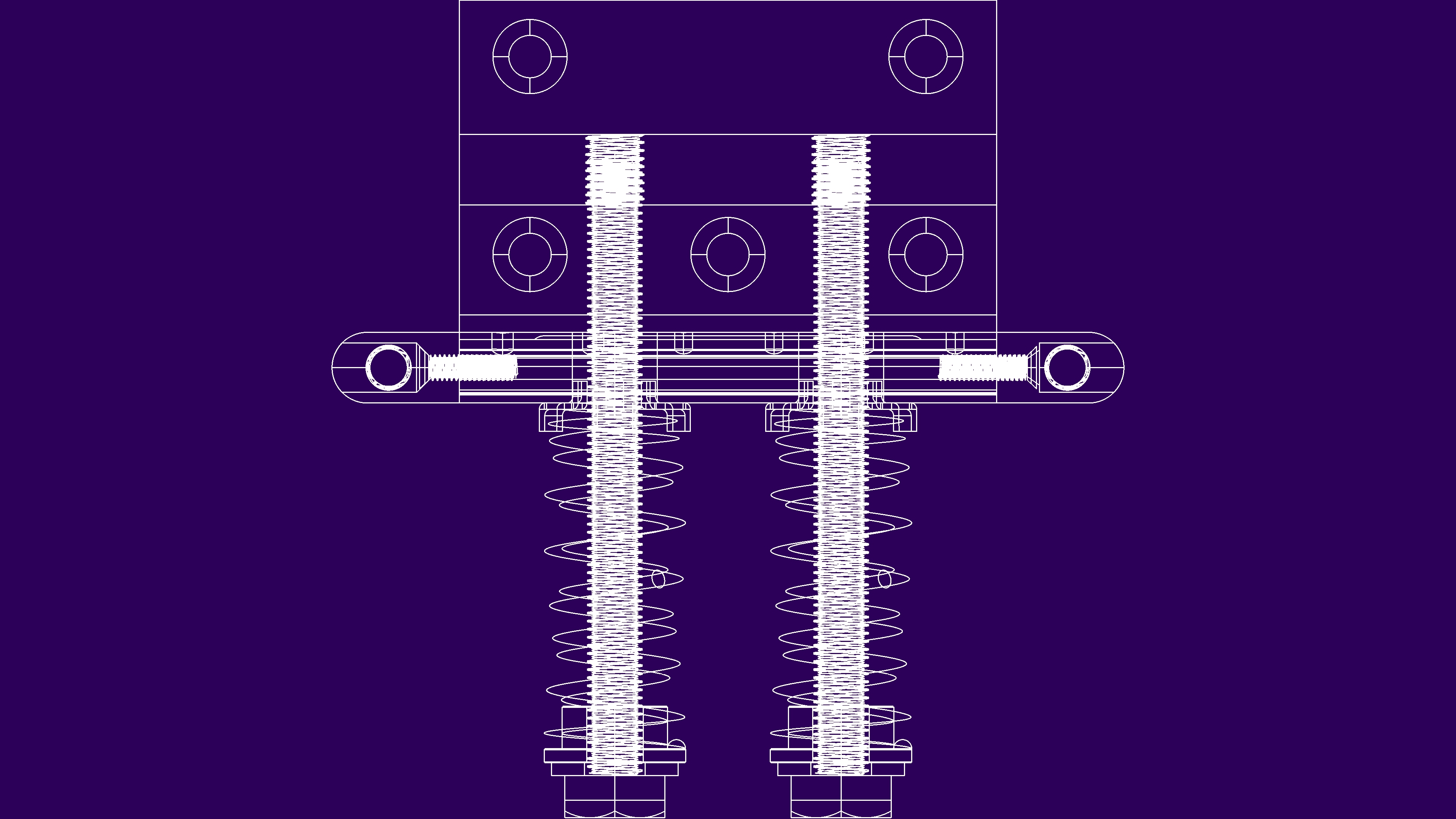

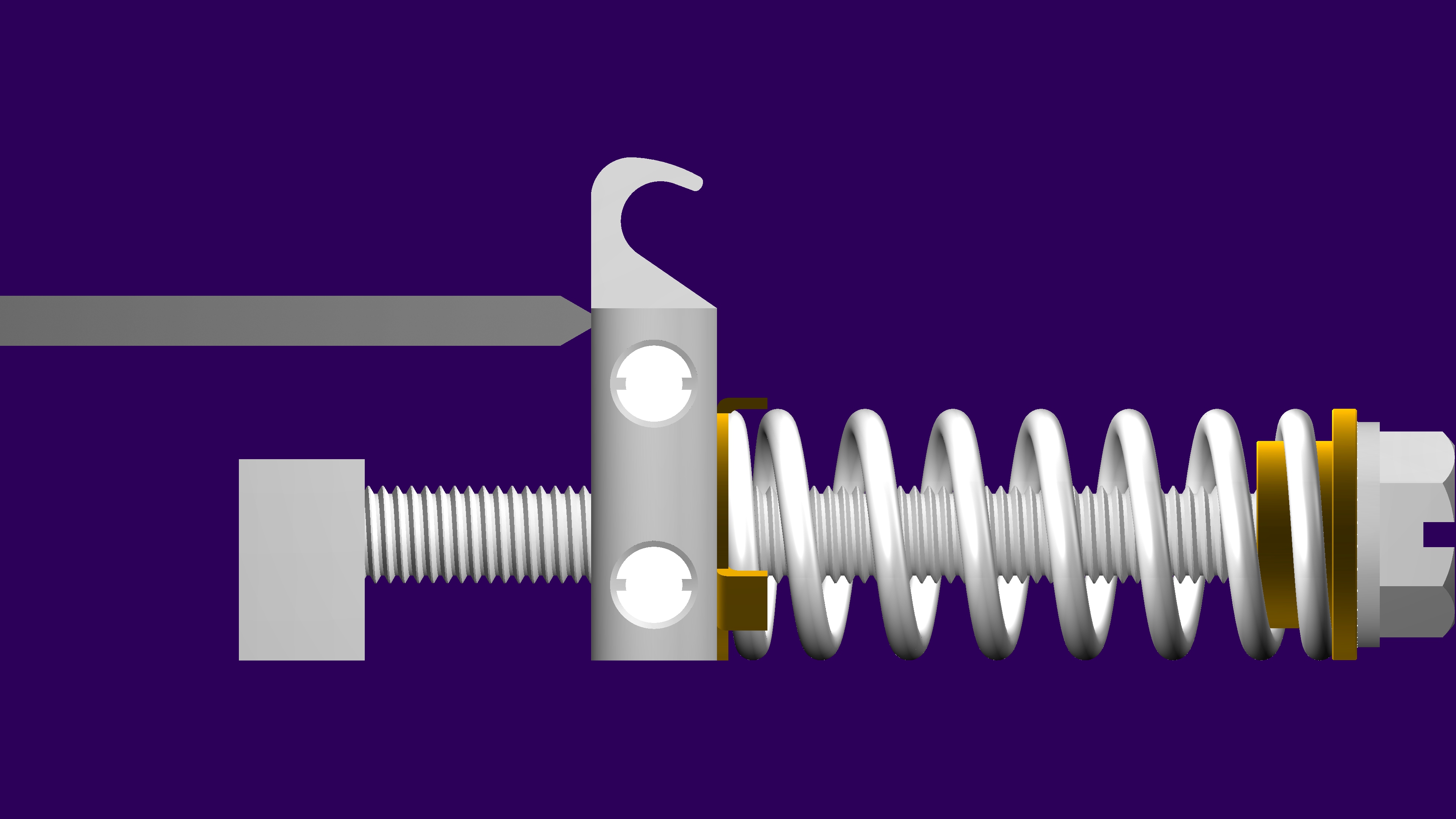

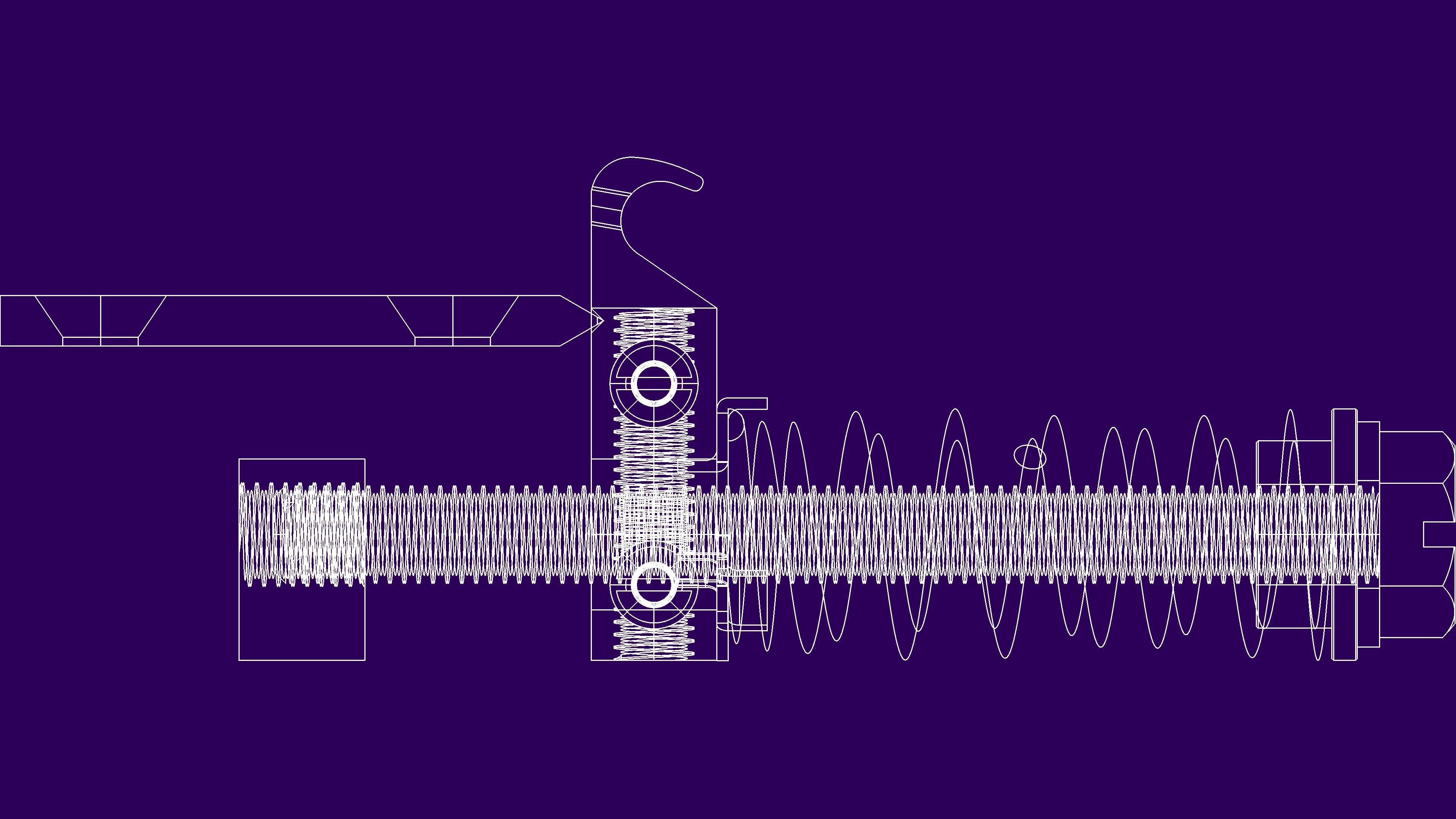

The tremolo (correctly the vibrato) system on Brian May’s Red Special guitar operates on the same principle (knife-edge bearing balanced by coil springs) as Fender’s two post floating tremolo. The main component is a vertical rocker block which retains the strings in a cowl. This pivots on a knife-edge bearing ground into a section of 1/8″ thick steel plate mounted horizontally, flush with the top of the guitar body.

String tension is counteracted by the compression force of two valve springs from a 1928 Panther motorcycle which butt against the rocker block and are located in the pass through holes by fasteners fashioned from brass plate. The moving components are held in position with two 1/4″ UNF thread hexagonal head set screws which are anchored into a section of 5/16″ thick x 1/2″ high steel bar located between the upper and lower guitar body sections. Slots are milled into the set screws heads to allow spring tension to be adjusted by inserting a flat blade screwdriver through holes in the back of the guitar body.

I published a 21 minute duration YouTube video in July 2025 covering the design details and fabrication of the three steel components in the Red Special tremolo assembly:

Because of the placement of the springs relative to the rocker block and their heavy duty specification, the Red Special’s tremolo system offers excellent pitch stability while allowing a large range of downward movement. Brian deploys these characteristics in conjunction with the natural tendency of the guitar to produce controllable feed back to create a range of dramatic and unearthly pitch variations he describes as “aeroplane noises, whale noises, divebombs and eerie screeches”.

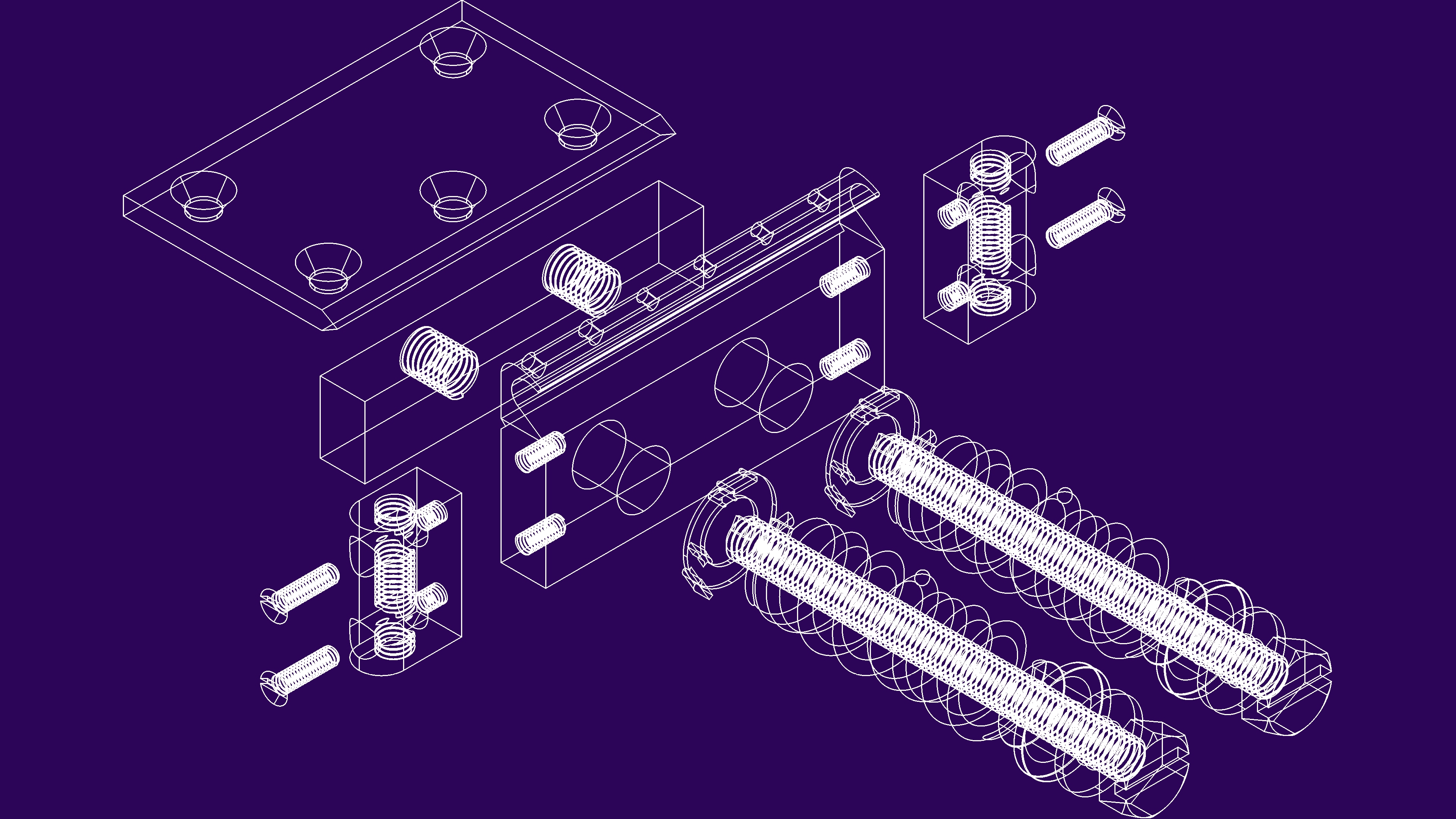

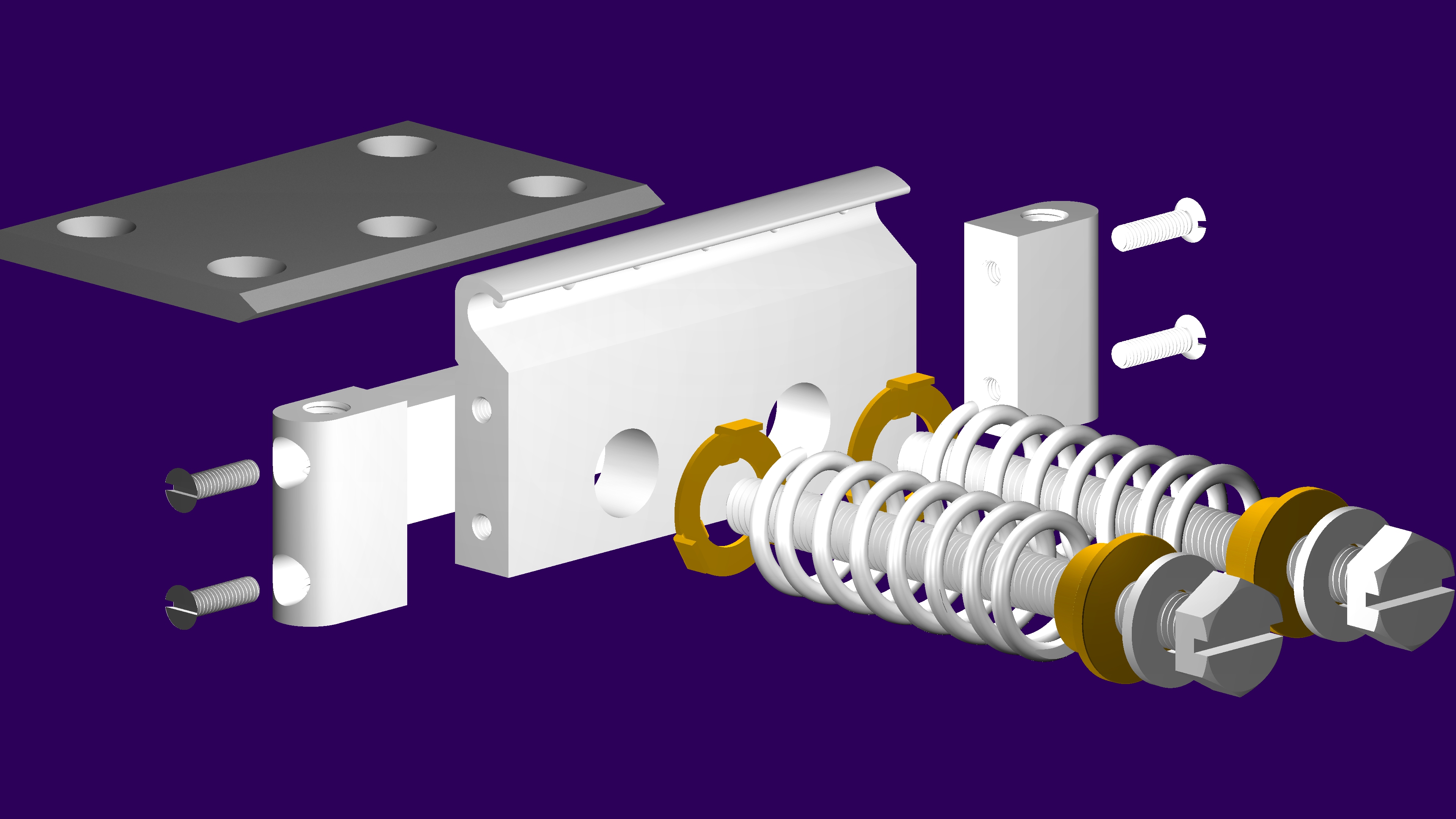

Renders from my CAD design interpretation of the original assembly are included in the gallery below. Note that the pass through holes are 3/8″ in my design (and Greg Fryer’s design for his three replica guitars) but are likely 7/16″ (11.1 mm) to 1/2″ (12.7 mm) on the original item noting that the Panther valve spring innner diameter is around 11.5 mm. 3/8″ is likely the minimum diameter required to accommodate the range of vertical pivoting movement and I can only use twist drills up to 10 mm diameter in the chuck of my mini drill press.

I published the second part of my video series examining the tremolo system in Brian May’s Red Special guitar in detail in August 2025. In this follow-up video I demonstrate the installation, set-up and basic function of the system with the help of a test rig. I also take the opportunity to compare my DIY components with a professionally made hardware set that is commercially available in the U.K., the relic hardware kit made by RS Mods. Please check out their website:

https://rsmods.uk

Component Specifications

Set screw retaining bar: 2 3/8″ wide, 1/2″ high, 5/16″ thick. Two holes with 1/4″ UNF thread spaced 1″ apart.

Knife-edge bearing plate: 2 3/8″ wide by 1 1/2″ long, 1/8″ thick. 60 degree fulcrum angle. Five countersunk screw holes to accept No. 10 x 1 1/4″ countersunk slotted wood screws.

Rocker block/tailpiece: 3 1/2″ to 3 9/16″ wide (main section 2 3/8″ wide with two 9/16″ wide side pieces, each attached by two screws), 1 1/4″ to 1 9/32″ high, 5/16″ thick. Two pass-through holes 7/16″ to 1/2″ diameter for the set screws spaced 1″ apart.

Coil springs: 1928 Panther motorcycle inner valve springs. Approximate specifications: Wire gauge: 14 SWG (0.080″), coil outer diameter: 5/8″, free length: 1 1/2″, solid length: 0.72″, active coils: 6.

Return to the FAQs Home Page

https://dsgb.net/faqs/